The Ultimate Guide to Professional Structural Steel Fabrication

Introduction to Structural Steel Fabrication

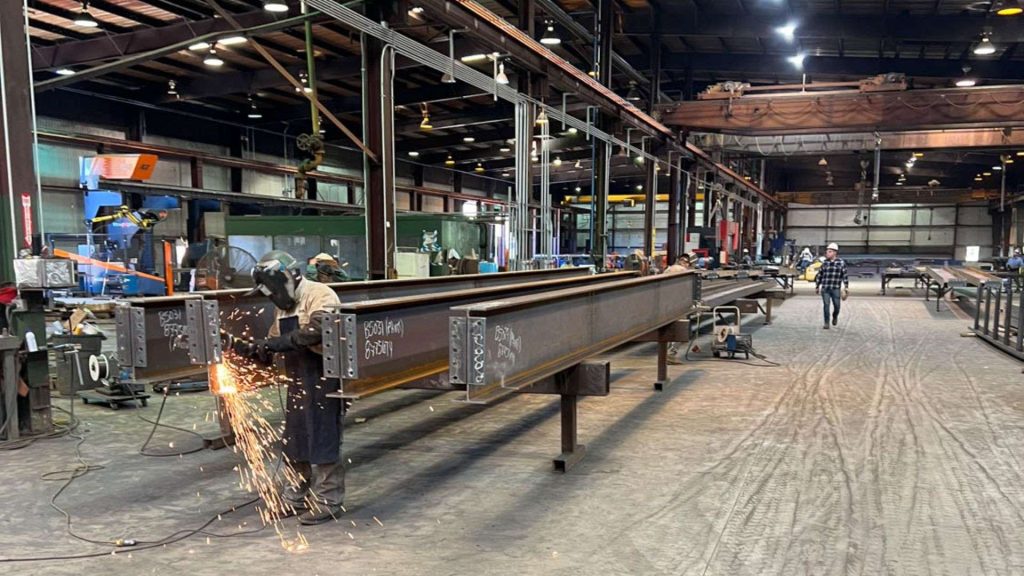

Structural steel fabrication is a crucial process in modern construction and industrial projects. It involves the precise cutting, shaping, and assembling of steel components to form structures that are strong, durable, and reliable. Companies like Noble Steel specialize in professional Structural steel fabrication to ensure projects meet exact specifications and safety standards. Understanding the fundamentals of structural steel fabrication helps businesses and engineers make informed decisions when planning construction projects.

What is Structural Steel Fabrication?

Structural steel fabrication is the process of transforming raw steel into customized components for buildings, bridges, industrial plants, and other structures. It includes a variety of processes such as cutting, welding, drilling, bending, and assembling steel parts. This process ensures that the steel components are ready for installation on-site. By using professional structural steel fabrication services, clients benefit from precision engineering, improved safety, and cost-effective construction.

Key Processes in Structural Steel Fabrication

Professional structural steel fabrication involves several stages to ensure high-quality outcomes:

Cutting

Cutting is the first step in structural steel fabrication. It involves shaping steel beams, plates, and sheets into the required sizes. Advanced cutting techniques, such as laser cutting and plasma cutting, provide high accuracy and minimal waste.

Welding

Welding is a critical process in structural steel fabrication that joins steel components together. Proper welding ensures structural integrity and durability. Skilled welders use specialized techniques depending on the steel type and project requirements.

Bending and Forming

Bending and forming processes shape steel into desired angles and curves without compromising strength. This step is essential for creating structural elements like beams, columns, and frames.

Drilling and Punching

Drilling and punching create precise holes for bolts and connections. Accurate drilling is crucial in structural steel fabrication to ensure seamless assembly and structural stability.

Assembly

The final stage in structural steel fabrication is assembly. Steel components are carefully aligned and joined to form the final structure. Professional assembly guarantees that the structure meets design specifications and safety codes.

Advantages of Professional Structural Steel Fabrication

Choosing expert structural steel fabrication services offers several benefits:

Precision and Accuracy

Professional fabrication ensures every component is manufactured with exact measurements. This reduces errors during construction and minimizes costly on-site adjustments.

Durability and Strength

Structural steel fabricated by professionals is designed to withstand heavy loads and harsh environmental conditions. It provides long-lasting durability for residential, commercial, and industrial projects.

Time and Cost Efficiency

By outsourcing structural steel fabrication, projects are completed faster with reduced labor costs. Fabricated steel components are delivered ready for installation, streamlining the construction process.

Safety Compliance

Professional structural steel fabrication adheres to strict safety standards and building codes. This ensures the final structure is safe, reliable, and compliant with regulations.

Common Applications of Structural Steel Fabrication

Structural steel fabrication is widely used across various industries:

Commercial and Residential Buildings

From skyscrapers to residential homes, structural steel fabrication provides reliable frameworks that support modern architecture.

Bridges and Infrastructure

Bridges, highways, and other infrastructure projects rely on structural steel fabrication for strength, flexibility, and long-term performance.

Industrial Facilities

Factories, warehouses, and plants utilize fabricated steel structures to support heavy machinery and industrial operations.

Specialized Structures

Structural steel fabrication is also used for stadiums, towers, and custom architectural projects requiring complex designs.

Choosing the Right Structural Steel Fabrication Partner

Selecting the right fabrication company is essential for project success. Key factors to consider include:

- Experience and expertise in structural steel fabrication

- Advanced machinery and technology for precision fabrication

- Compliance with safety and quality standards

- Timely project delivery and efficient logistics

- Transparent pricing and customized solutions

Noble Steel is an example of a trusted partner offering professional structural steel fabrication services tailored to meet diverse project requirements.

Future Trends in Structural Steel Fabrication

The field of structural steel fabrication continues to evolve with technological advancements:

- Automation and robotics are improving accuracy and reducing labor costs.

- Advanced 3D modeling and BIM (Building Information Modeling) enhance design precision.

- Sustainable fabrication methods are reducing waste and environmental impact.

By keeping up with these trends, companies offering structural steel fabrication can provide innovative and efficient solutions for modern construction challenges.

Conclusion

Structural steel fabrication is the backbone of modern construction, ensuring strength, durability, and precision in every project. From cutting and welding to assembly and installation, professional fabrication guarantees high-quality results that meet safety standards. Businesses and builders seeking reliable solutions should partner with experienced structural steel fabrication experts like Noble Steel to achieve superior outcomes. By investing in professional services, projects are completed efficiently, safely, and with exceptional structural integrity.